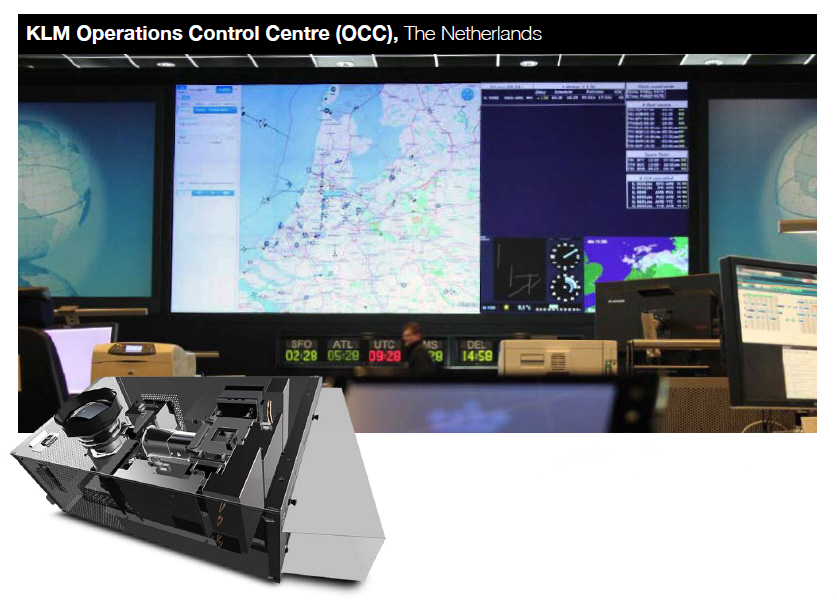

KLM Operations Control Centre (OCC), The Netherlands

27 Mar 2018

KLM’s Operations Control Centre (OCC), located at Schiphol-Oost in The Netherlands, manages virtually every aspect of the airline’s daily operations. As well as monitoring all flights to KLM’s 145 destinations worldwide,the OCC plays a crucial role in planning, engineering,maintenance and customer care.

KLM’s Operations Control Centre operates 24/7. Its open-plan space isdominated by a large central video wall displaying a huge variety of information,from live flight data to the latest news, weather reports andeven customer satisfaction ratings. As the main visual workspace forthe OCC’s numerous operator workstations, video wall performance andreliability is paramount. But achieving these high performancestandards using mercury lamp illuminated DLP rear projection, with its associated maintenance costs, was becoming increasingly costly.In line with KLM’s policies on cost reduction, energy efficiency andsustainability, the decision was made to upgrade the video wall tothe latest LED DLP cube technology.

System’s integrator AVEX was commissioned to provide a modern, energy efficient video wall solution for the OCC. Along with the upgrade of the video wall itself to reduce running costs and improve efficiency, improvements were also planned in the data processing and management of the video wall system, with all operations to be made possible from a single central control point at the Duty Manager Operations’ workstation. As the OCC is busy 24 hours a day, the upgrade had to be completed swiftly with the minimum of disruption to normal operations.

Thanks to thorough preparations, excellent teamwork between Mitsubishi, KLM and AVEX, and tight scheduling, AVEX technicians completed the replacement of the old video wall projectors with fifteen Mitsubishi Universal Upgrade engines in just three days, including final set-up adjustments, causing minimal disruption to the OCC’s vital operations. Along with the new projectors and image processing, a new Crestron touch panel interface provided the Duty Manager Operations with a single point of control to simplify operation of the video wall.

Mitsubishi Electric’s Upgrade models are available for almost all brands of DLP cubes manufactured over the last 15 years,enabling owners of all legacy mercury lamp systems to easily upgrade to the latest LED technology, quickly and efficiently. Universal Upgrade Engines employ state-of-the-art LED illumination but are designed as direct, slot-in replacements for older technologies, based on exactly the same physical architecture to ensure 100% compatibility with existing systems.Upgrading to Seventy Series from Mitsubishi Electric delivers not only the latest high brightness LED performance - and in some cases increased resolution - but dramatic savings in the total cost of ownership and the extension of the operational lifespan of existing facilities by over a decade.